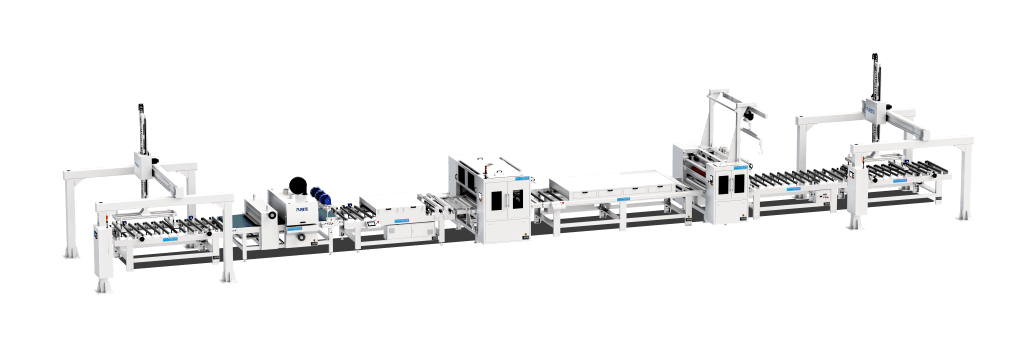

The T2 Automatic Laminating Production Line is designed for high-efficiency, automated panel lamination, integrating a gantry loading and unloading system to significantly reduce manual handling and labor intensity. This intelligent setup improves production efficiency, safety, and operational precision, making it ideal for continuous large-scale manufacturing.

The line supports PUR and hot-melt adhesive lamination for various substrates such as MDF, plywood, PET, PVC, and decorative sheets. It ensures smooth surface finishes, strong bonding, and uniform coating quality—perfect for furniture, doors, and interior wall panels. Composed of: Gantry loading, polishing and dust removal system, gluing machine, laminating machine, and unloading system.

technical specifications

114kw

TOTAL POWER

1200PCS/DAY

CAPACITY

6x45m

INSTALLATION AREA

30 days

PRODUCTION CYCLE

10m/min

LINE SPEED