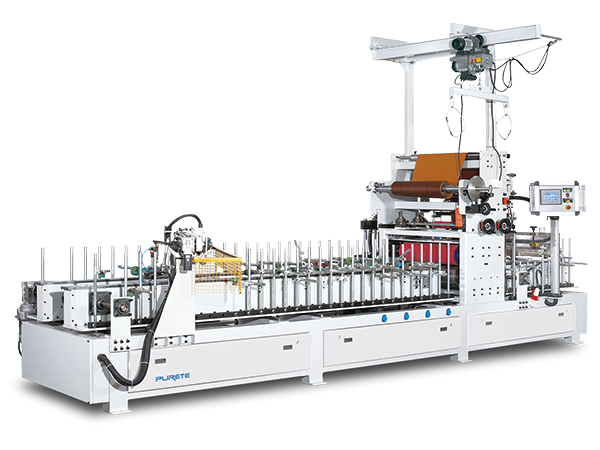

The FBF-66-L wide sheet wrapping machine is designed for efficient and high-precision wrapping of large panels. As the sheet moves along the conveyor, a specialized gluing device sprays and scrapes PUR or conventional hot melt adhesive onto the back of the wrapping material, simulating manual lamination.

The decorative surface material is then adhered to the substrate through point-by-point pressing by pressure rollers and molding wheels, achieving a seamless composite finish across the entire panel. Engineered for industrial-scale applications, the FBF-66-L ensures uniform adhesion, superior surface quality, and enhanced production efficiency. Ideal for furniture boards, laminated panels, and decorative sheet production, this automated wrapping system combines precision, high-speed operation, and reduced labor costs.

technical specifications

28KWH

TOTAL POWER

30 DAYS

PRODUCTION CYCLE

6x1x1.8m

INSTALLATION AREA

10,000 strips/DAY

CAPACITY

20-60M/MIN

LINE SPEED